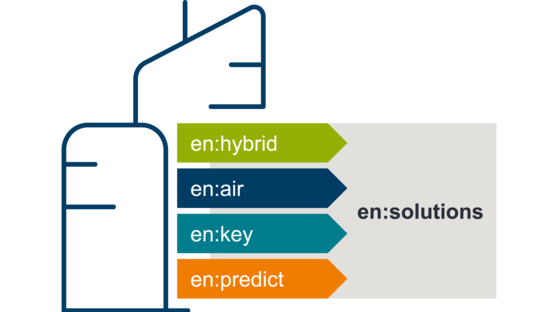

en:solutions – the flexible range of solutions for better climate and health protection

The smart building solutioneer Kieback&Peter has been connecting buildings and their business processes to form a smart complete system since 1927. This is the key to the sustainable, safe and economical operation of future-proof smart buildings.

To this end, the experienced building automation experts integrate tailor-made digital modules into their building technology systems. These then automatically ensure continually maximized energy efficiency and optimum health protection with a minimal carbon footprint. The main technical modules for doing so are the specialized control tools from en:solutions – digital sustainability technology for measurable savings effects.

Our solutions are more than just tried and tested; they also have the flexibility to be integrated into both

existing and new automation.

Reliably achieve sustainability targets with proven solutions

en:solutions incorporates a range of practical and proven control hardware and software for all types of buildings. Each solution module is optimized for a specific area of application and delivers concrete added value for the energy balance and carbon footprint of a building or entire property portfolio.

Kieback&Peter is continually expanding the range of en:solutions, which currently includes the self-learning individual room control en:key, the smart system orchestration en:hybrid, the predictive building control system en:predict and the demand-based ventilation control system en:air. The “en:” that features in all these names represents the highest level of en:energy efficiency.

>>

en:solutions is all about achieving maximum energy efficiency in buildings through proven hardware and software.

Efficiency gains that pay for themselves in just a short time

One particular feature of the en:solutions range is that every module can be flexibly integrated into both existing and new building automation systems. This modular principle means that it is also possible to gradually equip a building for the future through targeted improvements in efficiency, comfort and safety and therefore, for example, to achieve predefined savings targets in a methodical way. Each one of the solution modules has the potential to deliver high savings effects in day-to-day building operation. A further advantage is that it is generally relatively simple and requires only a small investment to integrate any of the en:solutions modules. It is possible for the systems to pay for themselves in less than two years from their integration.

This ensures climate protection makes real sense – including for Controlling. With the unique en:solutions, investors, owners and operators can reliably meet pressing challenges such as climate protection, decarbonization, urbanization, digitalization and sustainability with smart technical measures and thus preserve the value of their properties – and of course minimize costs.

>>