The Roots project is a milestone in sustainable urban development in Hamburg: Germany’s tallest timber construction high-rise represents not only innovative architecture but also a holistic approach to environmentally-friendly construction. Located in the Elbbrücken quarter of the HafenCity area of Hamburg, the building complex combines modern living space with a publicly accessible environmental education center – and uses environmentally-friendly materials and forward-looking building technology. A key element of this is the smart building automation from Kieback&Peter, which ensures continuous energy efficiency, comfort and an optimized carbon footprint.

Sustainable synergy of environmentally-friendly building materials and smart technology

Timber is experiencing somewhat of a renaissance as a building material – thanks to modern processing techniques such as cross-laminated timber (CLT), which enable stable, safe and ecologically beneficial building structures. The use of wood not only significantly reduces the carbon footprint, but also improves the indoor climate and opens up new architectural freedoms. In combination with smart building automation, energy consumption can also be reduced considerably.

Roots is an ideal example of sustainable synergy between wood as a building material and forward-looking technology. Krystian Grunwald and his team from the Kieback&Peter’s Hamburg location have created a smart automation solution for Germany’s tallest timber construction high-rise building. The control expert was enthusiastic about the project: “I found it extremely exciting from the very first moment to be able to work on a building that stands for the highest level of sustainability, from the building material itself to the technical equipment.”

Smart solutions for fire protection and sustainability

A high-rise building made of wood rather than reinforced concrete – does that make a difference for building automation? Krystian Grunwald explains: “Yes, the fact that the building is built out of wood definitely influenced our planning, particularly in the area of fire protection, where everything has to be 1000 percent safe. This is why we integrated safety systems such as smoke detectors, fire detectors and smoke extraction systems to a much greater extent in accordance with the fire protection concept.” Among other things, the team implemented the control of the mechanical smoke extraction system for the exhibition area. Smoke extraction takes place on the basis of the afterflow principle via the targeted control of the supply fans and a door that automatically opens to the outside in the event of a fire.

Central control panel for all technical systems

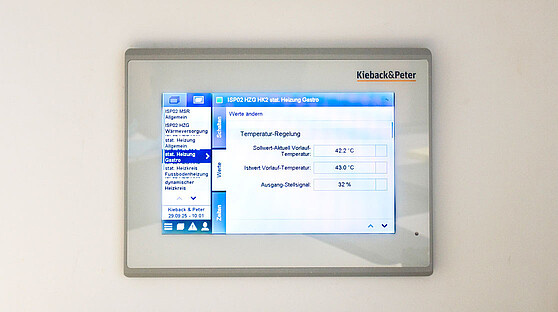

In addition to fire protection and automated ventilation in the apartments, the team’s tasks included the intelligent control of heating, ventilation and air conditioning in the exhibition and catering areas. A central control panel at the concierge desk in the lobby of the Roots building connects all automation areas and enables simple, central control.

In addition to the most resource-efficient operation possible, the building owners placed great value on a durable and economically efficient solution: “We only used high-quality automation components – many of which come from our own German production at Kieback&Peter,” Grunwald explains. “The result is a modern, digital control system that reliably controls all technical systems within Roots.”

Warm exhaust air heats cold fresh air – good for the environment, good for costs

The team developed a well-thought-out, user-friendly and economical solution to maintain a good indoor climate in the exhibition and catering areas. The system automatically ensures a constant and pleasant temperature according to the values set on the central control panel. To do so, the automation system uses the measured values of the integrated pendulum and wall sensors and precisely adjusts the output of the convectors. The ventilation system also operates fully automatically.

At the request of the operators, the team also integrated a manual override button for an increased supply of fresh air when there are lots of people in the cinema. “When the cinema is full, the ventilation power can be increased for three hours. It's a very effective and cost-saving solution.” The ventilation system in particular is responsible for sustainable operation: Heat exchangers extract the energy from the exhaust air and use it to bring the fresh air to temperature. This saves considerable amounts of heating energy.

Fiber optic cable for reliable building operation

From the underground car park to two heating systems and right to the top story – the team from Kieback&Peter has equipped the entire building with digital controls. The flexible and powerful controllers from Kieback&Peter regulate and control the entire building technology in seven interconnected control cabinets (automation centers). The experts connected two of them with fiber optics. Grunwald explains why: “The cable path between the two automation centers is more than 100 meters. The digital signals could be disrupted if using normal copper wires, which is why we chose to use fiber optics here.”

Efficient remote access when expert support is required

The central control panel in the lobby of the building allows all building technology parameters to be viewed and adjusted as required – for example, temperature or ventilation output. The client intended this task to be carried out by the concierge – after appropriate training.

“A good idea in theory, but concierges are often reluctant to make technical adjustments. That’s why we have also integrated our Connect CS remote maintenance – so that our team can easily provide remote support,” says the automation expert. When asked to sum up his thoughts on the Roots project, Krystian Grunwald responds in typical Hamburg fashion: “A real flagship project! Roots combines sustainable construction with modern technology – and we are delighted that our building automation system works perfectly here. Satisfied client, satisfied team – it doesn’t get better than this.”

Building information

- Building height: 65 meters, 19 stories – currently Germany’s tallest wooden high-rise building

- Construction type: Hybrid wood and reinforced concrete framework

- Timber content: More than 5,500 m³ of timber installed – primarily cross-laminated timber (CLT)

- Sustainability: Wood as a renewable raw material with a low carbon footprint, life cycle assessment for all building materials

- Digital building management: Smart control of heating, air conditioning and ventilation systems

- Mobility concept: Underground parking with car sharing offers, bicycle parking and electric charging points

![[Translate to Englisch:] Elbdeck [Translate to Englisch:] Elbdeck Hamburg](/fileadmin/_processed_/9/b/csm_11_Deutschland_Hamburg_Elbdeck_c766930218.jpg)

![[Translate to Englisch:] Qu4drans Paris [Translate to Englisch:] Qu4drans Paris](/fileadmin/_processed_/f/2/csm_Qu4drans_7e0a58bc67.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/d/csm_L_T_Sporthaus_Osnabrueck_Indoor_kieback-peter_d47dda6a97.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/6/f/csm_flevo-krankenhaus-aussenansicht-kieback-peter_7f540b4b4f.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_roots-hamburg-referenz-detailansicht_02e0d87a86.jpg)